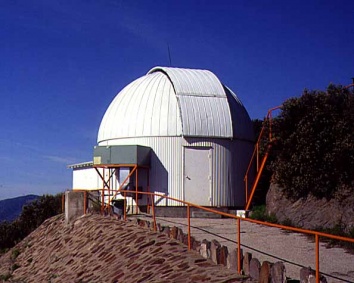

0.8-meter Telescope

McDonald Observatory is often cited for the Hobby-Eberly Telescope, one of the largest telescopes in the world. However, McDonald also hosts a number of smaller yet effective tools. The 2.7-meter Harlan J. Smith and 2.1-meter Otto Struve Telescopes are among these, but the smallest research telescope at McDonald Observatory is the 0.8-meter Telescope.

This small telescope owes its existence to one of its larger cousins. The 2.7-meter Harlan J. Smith Telescope was completed in the late 1960s. That telescope's mirror was made out of fused silica (Quartz), the state-of-the-art material for telescope mirrors at the time. After the central hole was cut out of this large mirror (necessary to allow incoming light to travel into its science instruments), McDonald Observatory decided to use all the costly glass that was left over.

The control room of the 0.8-meter Telescope.

This left-over glass was cut in half, creating two 30-inch mirror blanks. One of them was used to create the mirror for the 0.8-meter Telescope. The mirror is five inches thick and weighs in at over 250 pounds. It sits at the end of a tube that is almost eight feet long. The entire telescope is housed in a dome that is 20 feet wide. Construction of the original 0.8-meter Telescope was completed in 1970.

The control room of the 0.8-meter Telescope.

This left-over glass was cut in half, creating two 30-inch mirror blanks. One of them was used to create the mirror for the 0.8-meter Telescope. The mirror is five inches thick and weighs in at over 250 pounds. It sits at the end of a tube that is almost eight feet long. The entire telescope is housed in a dome that is 20 feet wide. Construction of the original 0.8-meter Telescope was completed in 1970.

One of the 0.8-meter Telescope's greatest advantages is its field of view. The telescope is able to observe a patch on the sky that is three-quarters of one degree across (the full moon is about one-half of a degree across). With this capability, the 0.8-meter Telescope is ideal for large search and survey projects.

Incidentally, the second mirror created from the left-over glass from the Smith Telescope serves as the primary mirror in McDonald Observatory's Mobile Laser Ranging System.

The telescope had undergone a refit as of November 2012.

The new telescope tube, mirror box, and mount, along with ancillary systems were manufactured by OMI (Optical Mechanics Incorporated) during 2011/2012, and initially installed in the dome structure during Aug. - Sept. of 2012 by a team from OMI, and McDonald Austin/West Texas including the OS and PP staff, and Gordon Wesley from Austin.

The telescope installation, debug, and final commissioning were performed by McDonald West Texas staff between November 2012 and approximately May of 2013. The telescope is now on the science calendar as a shared-risk resource for local operation.

The system is a hybrid, designed for local (in the dome), remote (via a network), and autonomous (robotic) operation. It uses a distributed motion control system, including high-precision servo motors, absolute optical encoders, and multi-axis digital motion controllers on the RA/HA and DEC axis. Both axes are steel-on-steel friction drives, utilizing a servo drive equipped with a hardened steel drive capstan, which directly engages a hardened steel drive roller. This is a zero-backlash drive design, capable precision motion accurate to within 50nm. The maximum slew rate is 24-radians/sec. (1375-degrees per second).

The telescope control system (TCS) is based on an open-systems solution, known as Talon. Talon is written in C and a scripting module system used to integrate motion control devices. The TCS supports full dome auto (the dome is encoded), planetarium-based, multi-catalog pointing (based on the open-systems XEphemeris), and uses a mesh-grid, high-precision pointing model that is continuously refined and extensible.

Telescope Facts |

|---|

Primary Mirror |

Diameter: 0.76 meters (30 in.) Weight: 118 kg (260 lbs.) Thickness: 12.7 cm (5 in.) Material: fused silica |

Telescope Tube |

Diameter: 0.89 m (35.2 in.) Length: 2.3 m (90 in.) |

Dome |

Diameter: 6.1 meters (20 ft.) |

Design |

Original Construction: 1970 Original telescope contractor: Boller and Chivens Dome contractor: Ash-Domes New Construction: 2012 Current telescope contractor: Optical Mechanics Incorporated |